Rethink Outcomes. Redefine Infrastructure.

This isn’t just about systems, it’s about outcomes. What if we could make circularity a baseline, not a bonus? What if compliance didn’t just tick a box, but built in sustainability from the start?

We design for that shift. We champion resource recovery, align sectors, and frame infrastructure not as a fixed constraint, but as a field of possibilities. With the right ambition and strategy, today’s challenges become catalysts for building new, adaptive pathways.

Where Design Really Begins

Before equipment. Before drawings.

Real design begins with defining what the system must do, how it must perform, and what reuse or recovery it should unlock.

YOUR SYSTEM’S STARTING POINT

Our Role: Structuring Intent to Support Integration

Our Role: Structuring Intent to Support Integration

From site constraints to reuse ambition, we don’t replace detailed designers, we bridge the gap between vision and execution. We work with clients early in concept development to shape, validate, and guide solution pathways.

Pathway Structuring

System logic and layout from the ground up

Reuse Alignment

Pair treatment goals with infrastructure realities

Delivery Alignment

Anticipate outcomes with actionable foresight

Circular Integration

Close loops across water, wastewater, and biosolids

The Logic We Bring: Five Steps to System Integration

The Logic We Bring: Five Steps to System Integration

These steps aren’t theoretical; they form the blueprint we use to convert risk into structure and ambition into action.

Step 1

Define Function & Integration

Clarify objectives and interfaces

Step 2

Understand Context & Constraints

Align goals with space, policy, and use

Step 3

Identify Logics & Technologies

Select fit-for-purpose design approaches

Step 4

Design for Automation

Embed smart controls and adaptive O&M

Step 5

Define Delivery Interfaces

Clarify handoffs across stakeholders

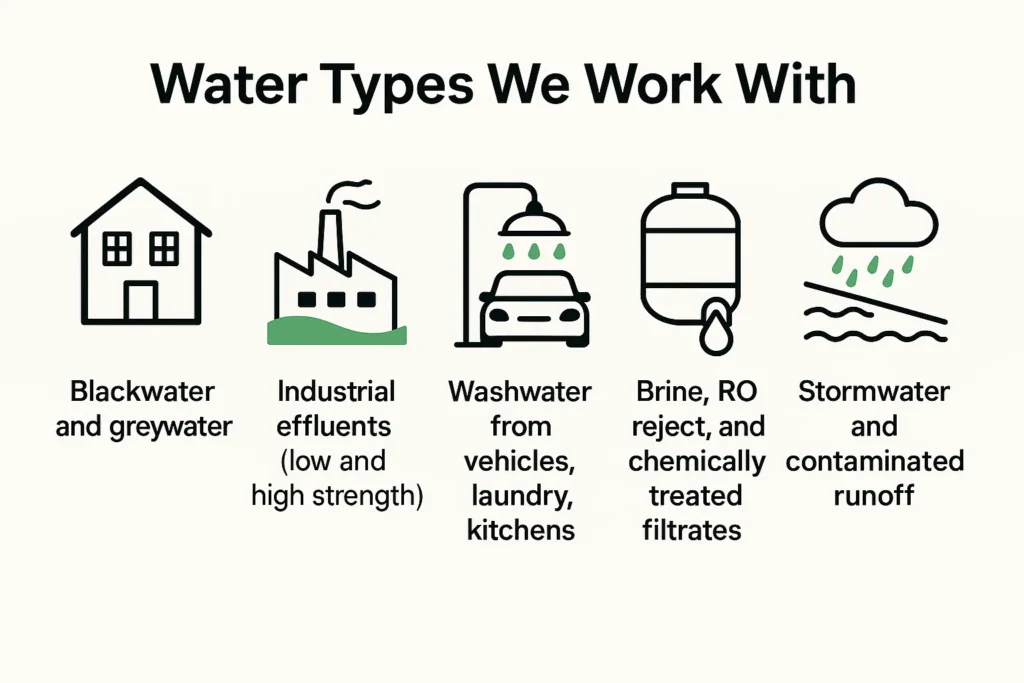

Water Types We Work With

Water Types We Work With

We categorize incoming water and wastewater streams based on their source, risk level, and reuse potential. The infographic below summarizes the five primary water types we address through FlowPlan+™ pathways.

Sector Pathways

Sector Pathways

We match water and waste challenges to reuse opportunities, tailored by sector.

Urban & Commercial Facilities

Facility Management & Labour Camps

Greywater reuse, package STPs.

Septicity, poor maintenance.

Hotels & Resorts

Decentralized reuse, FOG control.

Odour, seasonal variability.

Vehicle Wash & Bus Depots

Washwater recovery, grit/oil separation.

Sludge build-up, non-compliance.

Catering & Restaurants

FOG traps, compact treatment.

️ Blockages, discharge violations.

Laundries

Recovery and reuse systems.

Fouling, TDS scaling.

Industrial & Manufacturing

Food Manufacturing

Organic load management, ZLD framing.

️ Fouling, high COD discharge.

Paper Manufacturing

Closed-loop reuse, solids handling.

️ Clarifier overload, recycling inefficiencies.

Metal Industry

pH adjustment, heavy metal removal.

️ Hazardous sludge, treatment costs.

Agriculture, Cooling & Aquatic Systems

Stormwater-Impacted Sites

Sediment control, light treatment.

️ Runoff surges, clogging.

Aquaculture

Biosecurity-friendly reuse.

️ Nutrient spikes, pathogen control.

District Cooling Plants

TSE polishing, makeup water integration.

️ Scaling, corrosion, continuity gaps.

Explore FlowPlan+™ Modules

Explore FlowPlan+™ Modules

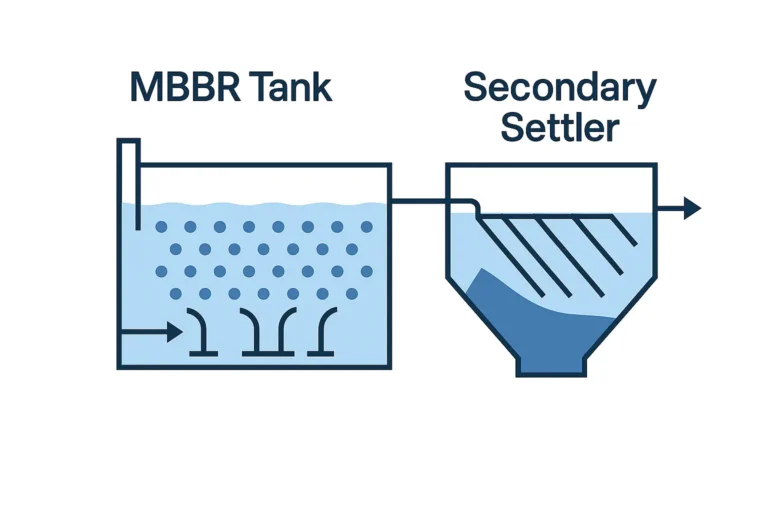

FP(MBBR+)™

Biological treatment with hybrid MBBR configurations (ASP/CAS variants).

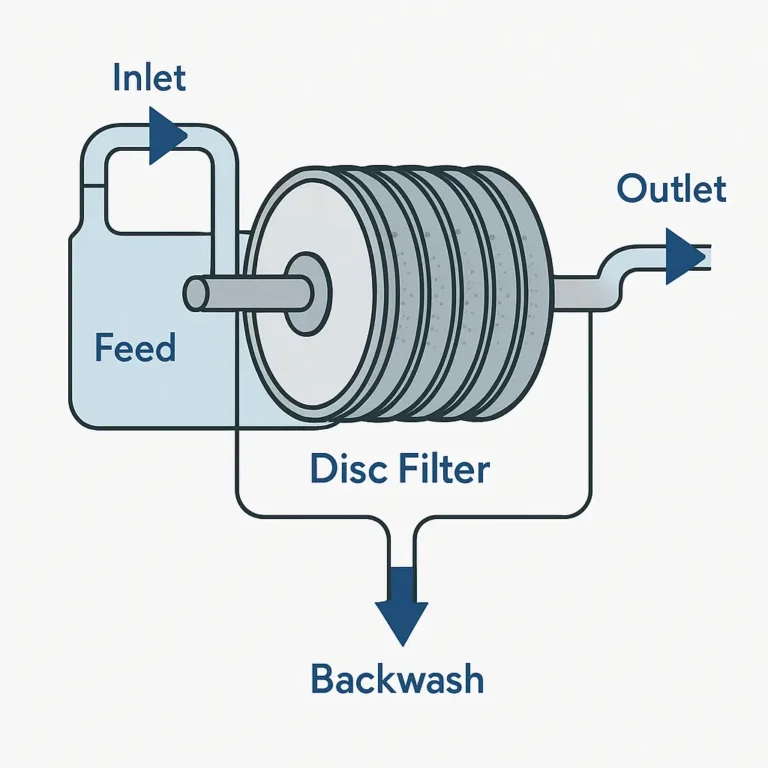

FP(Clari+)™ (Disc)

Disc filter for compact, high-volume tertiary filtration.

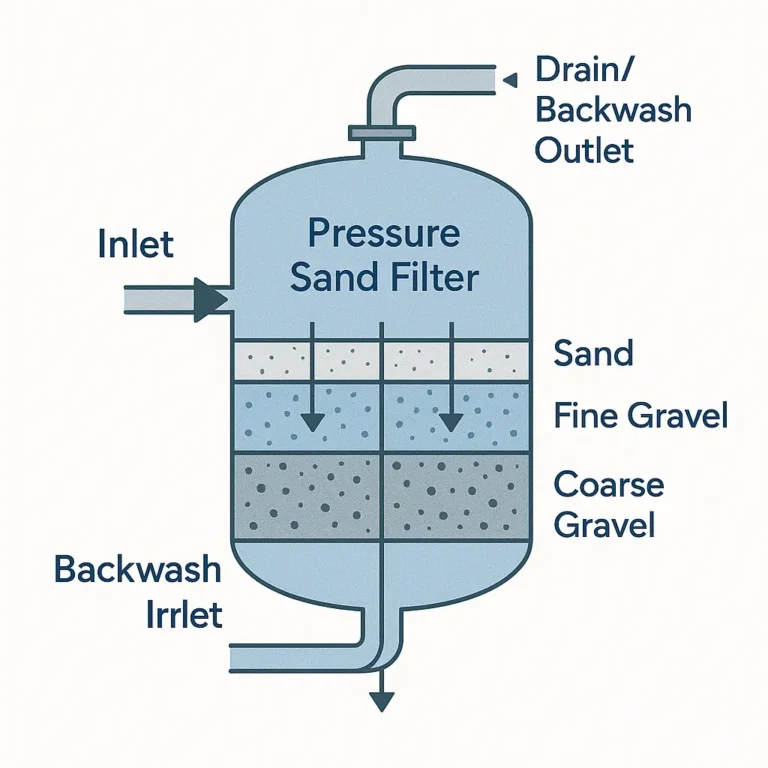

FP(Clari+)™ (PSF)

High-rate pressure sand filtration for particulate removal and polishing.

FP(ActivatedCarbon+)™

Activated carbon filtration for final-stage organic removal and adsorption of micropollutants. High-rate pressure sand filtration for particulate removal and polishing.

FP(Micra+)™ (UF)

Ultrafiltration for reuse assurance and suspended solids removal.

FP(Micra+)™ (RO)

Reverse osmosis module for high-purity output or ZLD readiness.

FP(Sludge+)™

Sludge treatment including dewatering, drying, composting, biofertilizer, or incineration pathways.

FP(Sludge+Compost)™

Thermophilic composting of dewatered sludge to Class A outputs.

FP(Sludge+Bio)™

Biofertilizer production through stabilized sludge and nutrient enhancement.

FP(Incineration+)™

Mono-incineration with ash recovery and energy integration.

FP(Batch+)™

Batch chemical treatment for high-precision coagulation, neutralization, or selective removal of complex pollutants.

Thermo+Loop™ (Heat)

Heat recovery from wastewater streams for process reuse.

Thermo+Loop™ (Cooling)

Effluent-based cooling loop design for HVAC/process systems.

FP(OxiClear+)™

Oxidation-based polishing using UV, ozone, or hydrogen peroxide , supports disinfection or advanced reuse.

FP(ZLD+)™

Zero Liquid Discharge solution targeting brine management and solids recovery using MVR/evaporation pathways.

From MBBR systems and disc filters to thermal sludge drying and ZLD, the modules below reflect configurations shaped by integration, not isolation. They illustrate how we adapt treatment to footprint, flow, and reuse goals.

Diagnostic Tools to FlowPlan+™ Linkages

Diagnostic Tools to FlowPlan+™ Linkages

Use these diagnostics to reveal constraints, risks, and opportunities for system design and reuse planning.

Area Footprint Diagnostic

Assess site space availability and footprint optimization opportunities.

→ FlowPlan(Prelim+)™

Design Support Form

Define goals, site context, and integration boundaries.

→ Preliminary FlowPlan+™ module match

System Healthcheck

Identify performance gaps and vendor upgrade needs.

→ Retrofit module selection

Reuse Planner

Plan reuse options based on flow and quality.

→ FP(TSE+), FP(Dual+Reuse)

Sludge Evaluator

Assess sludge quality and treatment options.

→ FP(Sludge+ReusePlan), FP(Sludge+Compost), FP(Sludge+Bio), FP(Incineration+)

Pretreatment Diagnostic

Characterize influent quality for pretreatment design.

→ FP(Batch+), FP(ROCore+), FP(Oxiclear+)

Retrofit Readiness Tool

Evaluate plant upgrade feasibility and constraints.

→ FP(ETP+Retrofit), FP(STP+Retrofit)

Thermal Integration Tool

Identify heat recovery and thermal process opportunities.

→ Thermo+ variants

Bottleneck Checklist

Spot process constraints limiting performance.

→ Process optimization support

Compliance Tool

Align system design with regulatory requirements.

→ Regulatory-aligned module recommendations

Diagnostic Details

Diagnostic Details

Design Support Form & Area Footprint Diagnostic (FlowPlan(Prelim+)™)

Foundation diagnostics for understanding site goals, context, and spatial constraints. Area Footprint Diagnostic assesses available space and optimization opportunities, critical for early layout decisions.

Links to preliminary FlowPlan+™ module configuration for site feasibility and design alignment.

System Healthcheck (Retrofit module selection)

Evaluates existing system performance and retrofit constraints. Guides retrofit module selection in FlowPlan+™ to optimize upgrade impact and cost-effectiveness.

Reuse Planner (FP(TSE+), FP(Dual+Reuse))

Maps flow and quality attributes to define reuse options maximizing water recovery and regulatory fit. Supports treated sewage effluent and dual reuse within FlowPlan+™.

Sludge Evaluator (FP(Sludge+ReusePlan), FP(Sludge+Compost), FP(Sludge+Bio), FP(Incineration+))

Assesses sludge characteristics and treatment pathways to optimize reuse or disposal. Aligns with FlowPlan+™ sludge and resource recovery modules for compliant, value-adding outcomes.

Pretreatment Diagnostic (FP(Batch+), FP(ROCore+), FP(Oxiclear+))

Characterizes influent quality for pretreatment design focusing on batch chemical dosing, membrane filtration, and advanced oxidation within FlowPlan+™.

Retrofit Readiness Tool (FP(ETP+Retrofit), FP(STP+Retrofit))

Evaluates plant upgrade feasibility including space, flow variability, and integration complexity to recommend retrofit modules in FlowPlan+™.

Thermal Integration Tool (Thermo+ variants)

Identifies heat recovery, thermal drying, and energy reuse opportunities across wastewater and sludge systems. Supports Thermo+™ modules in FlowPlan+™.

Bottleneck Checklist (Process optimization support)

Identifies operational bottlenecks limiting system performance and guides FlowPlan+™-aligned optimization strategies.

Compliance Tool (Regulatory-aligned module recommendations)

Ensures system design complies with regulatory frameworks by aligning diagnostics and modules to permit and discharge standards, minimizing project risk.

From Design to Action

From Design to Action

Once your system framing is complete, we help you carry it forward into practical, vendor-ready project configurations via FlowPlan+™, our structured planning and solution framework.

FlowPlan+™ is our modular system for bridging diagnostics with real-world implementation. It builds from your site’s challenges and technical context to configure project-ready, reuse-focused solutions.

Each FlowPlan+™ configuration aligns with recovery goals , water reuse, sludge valorization, odor management, or advanced effluent treatment , delivered through structured modules that can be combined, sequenced, or deployed standalone.

This is where insight becomes action. Explore the framework, review modules, and find the configuration that fits.

Ready to Begin?

Ready to Begin?

Whether you’re managing a facility, designing for reuse, or recovering from a failed solution, we help define a path that works.

Start a Design Conversation

Access FlowPlan™ Intake Tools

Explore Consulting & Diagnostic Services